- Equipment Manufacturing

Current Position:Home- Equipment Manufacturing - Equipment Manufacturing

Equipment Manufacturing|Quality excellence

,pursuit of perfection

After 30 years of development and innovation, our company has developed the new generation spindle cutter type CNC machine, as the machine developed for the precise processing of parts with small diameter, it adopts FANUC maintenance free servo-motor and features small size, big travel, high rotating speed of the principal axis, precise feeding, easy operation and maintenance, and smooth chip removal. The standard configuration of the machine includes the principal axis CS outline monitoring function, with different milling and cutting bits, it achieves high precision positioning of principal axis, end and section milling, cutting and drilling and precise processing of non standard parts. Clients are warmly welcome to our company for business.

Advantages of the Product:

? • Meet the demands of precise cutting and milling of metal parts with high efficiency and low cost

? • Adopt FANUC maintenance free servo-motor with high rotating speed of the principal axis, precise feeding, big travel, small size, smooth chip removal, easy operation and maintenance

? • With the principal axis CS outline monitoring function, after installing with different milling and cutting driving tools (3 driving tools), it achieves high precision positioning of principal axis, end and section milling, cutting and drilling and precise processing of non standard parts

? • Adopt FANUC high performance built-in spindle motor, under low noise and low vibration state, it achieves high speed and high precision control for the principal axis.

? • Combine the core knock-out switching device to achieve the processing function of the core knock-out machine

? • The innovative operation panel is concise and clear, it is visual and convenient for operation and programming.

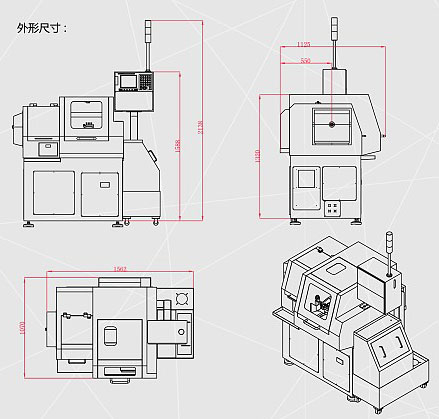

Dimension:

Standard Specification of the Machine

| Items | Unit | G15 | G20 | G20(Built-in Spindle) | Main Standard Auxiliary Devices | |

| Processing Capacity | 3-Color Signal Indicator | |||||

| Turning Diameter of the Machine Body | mm | Φ240 | Φ240 | Φ240 | Material Shortage Function | |

| Max Processing Diameter | mm | Φ100 | Φ100 | Φ100 | Cutter Damage Test Function Interface | |

| Max Bar Processing Diameter | mm | Φ15 | Φ20 | Φ20 | Cutter Base | |

| Max Processing Length | mm | 100 | 100 | 100 | Automatic Material Feeder Standard Interface | |

| Handle Diameter of Spring Clamp | mm | Φ19 | Φ28 | Φ28 | Digital Gas Pressure Test Device | |

| Principal Axis | Floor Plate of Machine | |||||

| Principal Axis Highest Rotating Speed | rpm | 6000 | 6000 | 8000 | Tools and Took Kit | |

| Principal Axis Speed Change | rpm | 0-6000 | 0-6000 | 0-8000 | Leakage Protection Device | |

| Principal Axis Max Through Hole Diameter | mm | Φ17 | Φ20 | Φ39 | Cutting Oil Device | |

| Quick Travel | Lighting Device | |||||

| X-Axis | m/min | 15 | 15 | 15 | Centralized Lubricant Device | |

| Z-Axis | m/min | 15 | 15 | 15 | Filtering and Pressure Reducing Valve | |

| Travel | Pneumatic Clamp Open/Close Device | |||||

| X-Axis Travel | mm | 310 | 310 | 310 | Fully Closed Housing | |

| Z-Axis Travel | mm | 210 | 210 | 210 | User-defined M Code Function | |

| Cutter | Elastic Tonghold 15#/20# | |||||

| Cutter Quantitys | ea | 10 | 10 | 10 | ||

| Outer Diameter Cutter Height | mm | □12×12 | □12×12 | □12×12 | ||

| Inner Diameter Cutter Diameter | mm | Φ25 | Φ25 | Φ25 | Special Auxiliary Device | |

| Cutter Base Center Height | mm | 49 | 49 | 49 | Principal Axis Inching Blow Function | |

| Motor | Material Catching Device | |||||

| X-Axis Servo-Motor Power | KW | 0.75 | 0.75 | 0.75 | Automatic Material Feeder Device | |

| Z-Axis Servo-Motor Power | KW | 0.75 | 0.75 | 0.75 | Principal Axis Positioning Device (Pneumatic) | |

| Principal Axis Motor Power | KW | 2.2/3.7 | 2.2/3.7 | 2.2/3.7 | Cs-Axis Outline Control | |

| Lubricant Motor | W | 35 | 35 | 35 | Materials Delivery Length Test Device | |

| Cooling Pump Motor | KW | 0.18 | 0.18 | 0.18 | Core Knock-Out Switching Device | |

| Cooling Tank | Driving Cutter Device | |||||

| Cooling Capacity | L | 60 | 60 | 60 | Driving Cutter Base | |

| Cooling Oil Pump Power | KW | 0.18 | 0.18 | 0.18 | Cutting Fluid Flow Rate Test | |

| Lubricating Device | Principal Axis Hard Tapping Function | |||||

| Lubricating Device Capacity | L | 2 | 2 | 2 | Material Puller | |

| Lubricating Pump Power | W | 35 | 35 | 35 | Pneumatic Cutter Device | |

| Others | Driving Cutter Hard Tapping Function | |||||

| Total Electric Capacity | KVA | 6KVA | 6KVA | 6KVA | ||

| Weight | Kg | 1250 | 1350 | 1350 | ||

|

Dimension (L×W×H) |

mm |

1450×1070 ×1640 |

1450×1070 ×1640 |

1450×1070 ×1640 |

||

| Precision | ||||||

| Positioning Precision | mm | 0.002 | 0.002 | 0.002 | ||

| Resetting Precision | mm | ±0.001 | ±0.001 | ±0.001 | ||

| Principal Axis End Jump | mm | 0.001 | 0.001 | 0.001 | ||

| Principal Axis Radial Jump | mm | 0.001 | 0.001 | 0.001 |